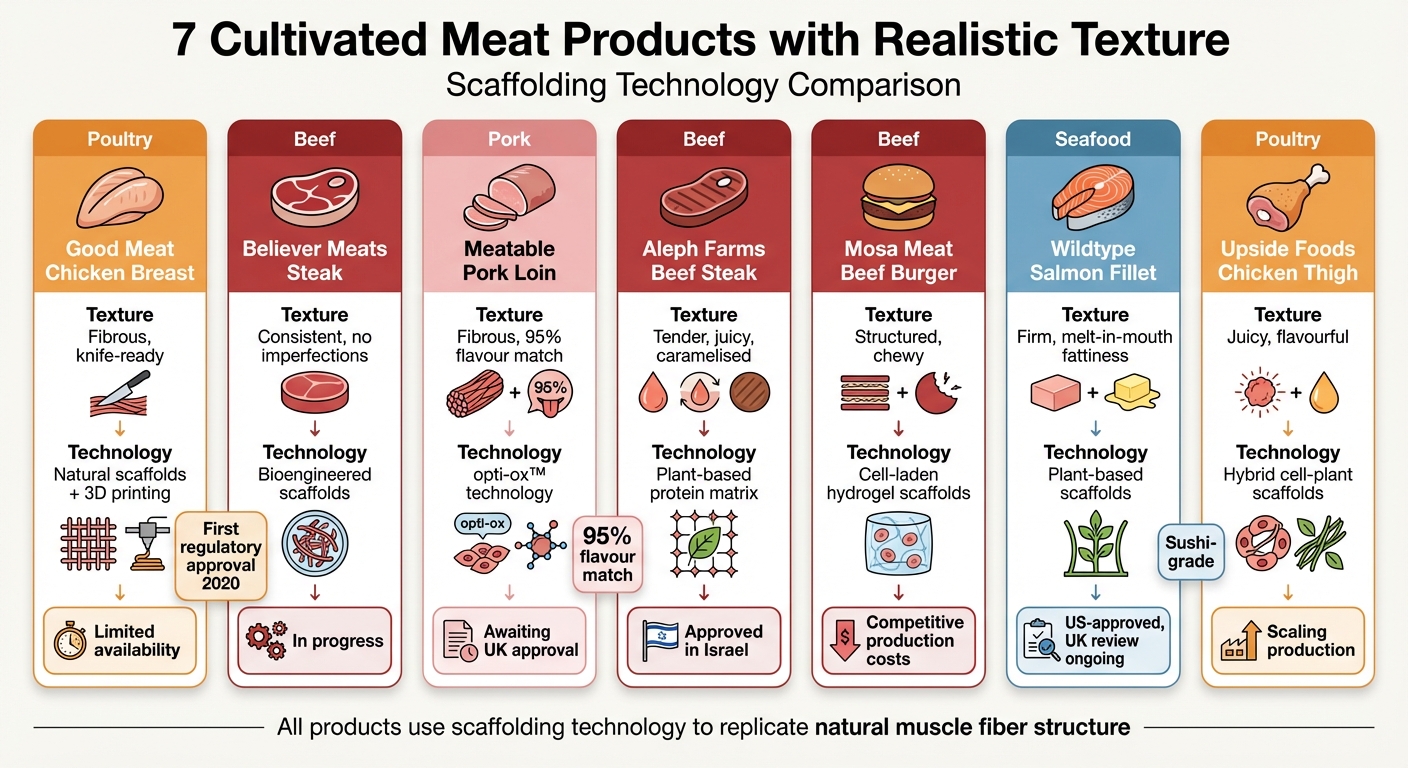

Cultivated meat is changing how we think about food by growing animal cells into real meat without farming or slaughter. The biggest challenge? Replicating the texture of whole cuts like steak or chicken breast. This is where scaffolding technology steps in, guiding cells to form the muscle and fat structures needed for realistic texture.

Here are seven cultivated meat products making strides in texture:

- Good Meat Chicken Breast: Uses natural scaffolds and 3D printing for fibrous, knife-ready chicken. Limited availability.

- Believer Meats Steak: Consistent texture with bioengineered scaffolds, free of gristle and fat pockets.

- Meatable Pork Loin: Achieves 95% flavour match to pork using opti-ox™ technology. Awaiting UK regulatory approval.

- Aleph Farms Thin-Cut Beef Steak: Combines Angus muscle cells with plant-based scaffolds for a tender, juicy bite.

- Mosa Meat Beef Burger: Mature muscle fibres and cultivated fat deliver structure and chew. Scalable production in progress.

- Wildtype Salmon Fillet: Sushi-grade salmon with plant-based scaffolds for omega-3 richness and delicate texture.

- Upside Foods Chicken Thigh: Blends cultivated cells with plant scaffolds for juicy, flavourful chicken.

These products aim to replicate the texture, bite, and cooking behaviour of meat while addressing the environmental and ethical concerns of traditional farming. Scaffolding technology plays a critical role in achieving these results.

Quick Comparison

| Product | Texture Focus | Scaffolding Tech Used | Availability (as of 2026) |

|---|---|---|---|

| Good Meat Chicken Breast | Fibrous, knife-ready | Natural scaffolds, 3D printing | Limited |

| Believer Meats Steak | Consistent, no imperfections | Bioengineered scaffolds | In progress |

| Meatable Pork Loin | Fibrous, 95% flavour match | opti-ox™ technology | Awaiting UK approval |

| Aleph Farms Beef Steak | Tender, juicy, caramelised | Plant-based protein matrix | Approved in Israel |

| Mosa Meat Beef Burger | Structured, chewy | Cell-laden hydrogel scaffolds | Competitive production costs |

| Wildtype Salmon Fillet | Firm, melt-in-mouth fattiness | Plant-based scaffolds | US-approved, UK review ongoing |

| Upside Foods Chicken Thigh | Juicy, flavourful | Hybrid cell-plant scaffolds | Scaling production |

These advancements are pushing cultivated meat closer to everyday dining tables, offering a future with less environmental impact and no animal slaughter.

7 Cultivated Meat Products Texture Comparison Chart

Dr. Amy Rowat: Marbling cultivated meat with hydrogel scaffolds

sbb-itb-c323ed3

1. Good Meat Cultivated Chicken Breast

Good Meat has made history by being the first to secure regulatory approval for cultivated meat in Singapore (2020) and the United States (2023) [4]. Their cultivated chicken breast represents a step forward from earlier ground-format cultivated meat products, thanks to advancements in their production methods, particularly in scaffolding technology.

Scaffolding Technology Used

Good Meat relies on what they call "natural" scaffolding paired with 3D food printing to create structured, whole-cut meat products [4]. This scaffolding is designed to replicate the extracellular matrix (ECM) found in traditional animal tissue. By mimicking these natural structures, the scaffolding guides cells to grow and organise into muscle, fat, and connective tissue [4].

Texture Realism Compared to Conventional Meat

The use of this scaffolding allows Good Meat to replicate the fibrous structure of conventional chicken breast. This method produces a texture that mimics the chew and resistance of traditional chicken, delivering a knife-ready, fibrous feel that meets consumer expectations [4]. Unlike earlier cultivated meat products, which were restricted to ground meat formats, this approach tackles the more complex challenge of creating whole cuts.

Current Availability or Expected Launch Date

For now, availability is limited due to production capacity challenges. However, in early 2023, Good Meat transitioned to using serum-free media, eliminating the need for animal-derived growth factors. This shift addresses both ethical concerns and cost barriers. The production process typically takes two to eight weeks, from cell banking to final packaging [5].

2. Believer Meats Cultivated Steak

Believer Meats' cultivated steak is designed to have an "ideal consistency", addressing the unpredictable texture variations often found in traditional beef cuts[6]. This breakthrough showcases how advancements in scaffolding technology are transforming the texture of cultivated meat to closely resemble its conventional counterparts.

Scaffolding Technology Used

Believer Meats has refined the art of creating realistic textures by employing advanced scaffolding techniques. Using a bioengineered process, they replicate the muscle fibre structure found in traditional meat. By growing their steak in a controlled environment, they can precisely adjust both the nutritional content and physical texture. The result? A product that looks, cooks, and even sizzles just like a conventional steak[6].

Texture Realism Compared to Conventional Meat

The cultivated steak boasts a consistent texture, free from antibiotics, artificial preservatives, or added colours. In a health comparison with traditional meat, it eliminates common imperfections such as fat pockets, gristle, and connective tissue, delivering uniform quality throughout.

Consumer Feedback on Mouthfeel and Bite

Thanks to controlled cell growth, every bite offers the same satisfying texture. Consumers frequently describe the experience as delivering a "perfect" bite, with a sensory profile that rivals traditional steak[6]. This meticulous engineering ensures a premium eating experience, replicating the flavour and feel of high-quality steak without the inconsistencies often found in traditional cuts.

3. Meatable Pork Loin

Meatable's cultivated pork loin aims to closely replicate the premium texture and flavour of traditional pork cuts. The company reports a 95% flavour match to conventional pork[7], with texture playing a key role in creating an authentic dining experience. Using advanced scaffolding techniques, Meatable continues to fine-tune the texture of its products to meet consumer expectations.

Scaffolding Technology Used

Meatable utilises its patented opti-ox™ technology, licensed from bit.bio, to efficiently transform pluripotent stem cells into muscle and fat cells with 100% accuracy. This process unfolds in two stages:

- Phase 1: Cell sourcing and proliferation.

- Phase 2: Maturation, where scaffolding techniques are applied to develop the fibrous structure and mouthfeel of premium pork loin.

Through this controlled process, Meatable grows mature muscle and fat cells that mirror the texture and bite of traditional pork cuts[7].

Current Availability or Expected Launch Date

As of November 2025, cultivated meat products are still undergoing regulatory review in the United Kingdom[5]. While Meatable has not revealed a specific launch date for its pork loin, the UK is one of ten countries actively evaluating cultivated meat for approval.

4. Aleph Farms Thin-Cut Beef Steak

Aleph Farms' thin-cut steak, known as Aleph Cuts, is among the first cultivated meat products designed to closely replicate the sensory experience of traditional beef. By cultivating Angus muscle and collagen cells on a plant-based protein scaffold, the company aims to deliver what it describes as a "satisfying bite" paired with a "tender and juicy" interior [8].

Texture Realism Compared to Conventional Meat

Aleph Cuts achieves a texture remarkably similar to conventional beef, thanks to the inclusion of the same amino acids found in traditional meat. This ensures proper caramelisation during cooking, resulting in a crust that enhances the rich, savoury interior [8]. Unlike plant-based substitutes, this product incorporates actual muscle and collagen cells, setting it apart from alternatives [8].

"With a satisfying bite, the caramelized crust gives way to a rich and savory interior that is tender and juicy." - Aleph Farms [8]

TIME Magazine described the flavour as "pure meat" in December 2022, and in January 2023, the product received Kosher certification from the Israeli Chief Rabbi [8]. This highlights the importance of scaffolding technology in mimicking the familiar textures of meat, a key focus in the cultivated meat industry.

Scaffolding Technology Used

Aleph Farms employs a plant-based protein matrix to support cell growth. This matrix is designed to be porous, offering a large surface area that enhances oxygen flow. This setup helps the cells form muscle fibres naturally, eventually maturing into tissue [8]. These advancements not only improve the product's texture but also pave the way for regulatory progress and market readiness.

Current Availability or Expected Launch Date

As of late 2025, cultivated meat products are still undergoing regulatory progress in the UK. Aleph Cuts, however, made history in January 2024 by becoming the first cultivated meat product to gain regulatory approval in Israel [5][10]. While no specific UK launch date has been announced, Aleph Farms is collaborating with chefs like Eyal Shani and Marcus Samuelsson to fine-tune the culinary experience before the product hits the market [9]. Their use of a plant protein scaffold underscores the importance of texture replication in the development of cultivated meat.

5. Mosa Meat Cultivated Beef Burger

Mosa Meat is pushing the boundaries of cultivated meat with its beef burger, focusing on refining the authenticity of its product. By maturing muscle and fat precursor cells, the company replicates the cell structure of traditional beef. This process ensures the presence of key meat proteins like actin and myosin, which are essential for replicating the taste and texture of conventional beef [12].

Texture Realism Compared to Conventional Meat

The burger's texture comes from mature muscle fibres, which provide structure and chew, while cultivated fat adds tenderness and enhances the overall mouthfeel. Microscopic analysis reveals that these muscle fibres are almost indistinguishable from those found in traditional beef. The cultivated fat undergoes a natural maturing process, known as adipogenesis, resulting in a triglyceride profile that mirrors conventional beef [12].

"Muscle fibres give meat its structure and chew, and within muscle fibres the rich colour of meat and proteins are produced." - Tim van de Rijdt, Chief Business Officer, Mosa Meat [12]

The production timeline is impressive: muscle fibres mature in just 7 days, and fat tissue takes 28 days, a stark contrast to the more than two years required to raise conventional cattle [12].

Scaffolding Technology Used

Mosa Meat employs advanced scaffolding technology, using a cell-laden dissolved hydrogel to precisely position cells within a specialised apparatus. This setup supports the growth and differentiation of cells into mature tissue. By relying on naturally committed precursor cells, the company avoids genetic modification, ensuring a product that closely resembles traditional beef. Remarkably, a single 0.5-gram biopsy can yield up to 80,000 hamburgers [1][11]. This innovative approach highlights the progress being made towards making cultivated meat a commercially viable option.

Current Availability or Expected Launch Date

As of February 2026, Mosa Meat reached a major milestone by achieving production costs that are competitive with conventional beef. The company secured €15 million in additional funding and is actively working with global regulators to manage approval costs. While cultivated meat is still under regulatory review in the UK, Mosa Meat has partnered with Esco Aster in Singapore to establish commercial-scale production facilities. Although no specific UK launch date has been confirmed, initial market offerings are expected to come at a premium price, with costs anticipated to decrease as production scales up [13][11].

6. Wildtype Salmon Fillet

Wildtype has developed cultivated seafood that mirrors the texture and quality of premium Pacific salmon. Its sushi-grade salmon fillet is crafted for dishes like sashimi, nigiri, crudo, and ceviche. By combining real salmon cells with plant-based scaffolding, Wildtype creates a product that offers the same omega-3 profile and textural complexity as traditional salmon - without concerns like mercury, microplastics, or parasites [14].

Texture Realism Compared to Conventional Meat

Wildtype's salmon achieves the delicate balance of firmness and rich, melt-in-your-mouth fattiness that defines high-quality sushi. Recreating this texture is no easy feat, as fish collagen's low thermal stability makes it tricky to maintain the structural integrity needed for slicing and raw preparation. The product is presented in a "Salmon Saku" format, a Japanese-style block of raw fish specifically designed for sashimi slicing [14].

Scaffolding Technology Used

To replicate the structure of a natural fillet, Wildtype uses an innovative method that combines cultivated salmon cells with plant-based scaffolding. This allows the cells to grow and mature into a three-dimensional structure resembling a fish fillet. The production process takes place at Wildtype's demonstration-scale Fishery in San Francisco, where cells are cultivated in stainless steel tanks, nourished with a special nutrient blend, and integrated with scaffolding to form the final product [14]. This approach is key to achieving both the desired texture and production scalability.

Current Availability or Expected Launch Date

As of November 2025, Wildtype's cultivated salmon is undergoing regulatory review in the United Kingdom, though it has already been approved for sale in the United States. The advancements in scaffolding technology are not only refining the product's texture but also aiding regulatory progress. Additionally, Wildtype operates a tasting room, "The Dock", at its San Francisco facility, where visitors can sample the product. The UK's Food Standards Agency predicts that cultivated meat products, including Wildtype's salmon, could hit British retail shelves by late 2026 or 2027, pending safety assessments and regulatory approval [14].

7. Upside Foods Chicken Thigh

Upside Foods' UPSIDE Chicken Essentials line aims to replicate the taste and texture of traditional chicken by combining cultivated cells with plant-based ingredients. This process involves growing meat directly from animal cells in a controlled environment at their "EPIC" production facility. The goal? To recreate the flavour and bite of conventional chicken as closely as possible [16].

How It Matches Conventional Texture

The texture of Upside Foods' chicken is achieved through scaffolding technology, which helps cells align into structures that resemble natural muscle fibres. During the growth process, mechanical tension ensures the cells form into authentic muscle fibres. Combined with integrated fat cells, this approach provides the juiciness and bite that chicken thighs are known for [15].

Innovative Scaffolding Technology

The company employs a hybrid technique, blending cultivated chicken cells with plant-based scaffolding. This scaffolding mimics the extracellular matrix, guiding the cells to develop into a three-dimensional structure that mirrors traditional chicken [15][16].

Feedback on Taste and Mouthfeel

Culinary experts have praised the product's taste and texture. Dominique Crenn, a three-star Michelin chef and owner of Atelier Crenn, shared her thoughts after sampling the cultivated chicken:

"When I tasted it, I was like... okay, this is the future. I love UPSIDE." [16]

The product has also caught the attention of prominent influencers like MrBeast, who visited the facility to try it. Upside Foods describes their cultivated meat as "flavourful, tasty, tempting", and "delicious", with positive feedback supporting their production growth [16].

Availability and Next Steps

Upside Foods is actively scaling its production efforts. Interested consumers can join a waitlist on the company's website to receive updates and even sign up for facility tours [16].

Why Texture Matters in Cultivated Meat

Texture is crucial for the success of Cultivated Meat. When you bite into meat, you expect a firm resistance, a clean break, and a satisfying chew. These sensory experiences define what we associate with meat. If Cultivated Meat fails to deliver this, it's unlikely to win over consumers [18][19].

As discussed earlier, scaffolding plays a key role in replicating the structure of conventional meat. Traditional meat is made up of about 90% muscle fibres and 10% connective tissue, which together create its hardness, springiness, and chewiness. Reproducing this intricate composition is no small task [18]. Scaffolding technology tackles this by imitating the extracellular matrix (ECM). For example, scaffolds that match the stiffness of skeletal muscle (2–12 kPa) and fat tissue (0.2–1.0 kPa) provide the right environment for cells to develop the desired texture. In 2022, Biotech Foods demonstrated this potential by creating a cultivated sausage with hardness and chewiness comparable to processed meat, using advanced scaffold designs [18].

Producing whole cuts like steaks is even more complex. Techniques like electrospinning and 3D bioprinting are used to align muscle fibres in parallel patterns, mimicking the natural structure of animal meat. To achieve fat marbling - the streaks that contribute to juiciness - adipocytes (fat cells) are either integrated directly into the muscle or separate muscle and fat tissues are fused using precise methods.

The texture and consistency challenges don’t stop at raw meat. Cultivated Meat must also behave like traditional meat when cooked. A 2022 study in npj Science of Food revealed that boiling increased the hardness of cell-sheet meat from 9.07 kPa to 14.69 kPa, mirroring the protein denaturation seen in conventional meat [17]. This thermal response highlights that properly structured Cultivated Meat not only looks like the real thing but also cooks and tastes the same.

These advancements in texture underscore the importance of scaffolding and mark significant progress towards creating the next wave of Cultivated Meat products.

Cultivated Meat Shop: Your Guide to the Future of Meat

Cultivated Meat Shop is paving the way for cultivated meat's introduction in the UK, bridging the gap between cutting-edge science and everyday understanding. While products like textured steaks and fillets aren't available just yet, the platform offers straightforward and easy-to-digest content to help you stay informed. It complements the earlier discussion of textured cultivated meat products by breaking down the science behind them.

The site explains how scaffolding technology plays a key role in replicating the texture of traditional meat. It also keeps you in the loop about product launches and the types of cultivated meat on the horizon. For instance, "unstructured" products like burgers and nuggets may hit the shelves first, while "fully-structured" cuts like steaks and fillets require more advanced techniques to produce [2].

In addition to product insights, Cultivated Meat Shop shines a light on the environmental benefits of this innovation. Traditional livestock farming accounts for roughly 14.5% of global greenhouse gas emissions [3][20]. Cultivated meat offers a way to enjoy meat without the heavy environmental cost. By combining explanations of the technology with its potential to reduce emissions, the platform provides a well-rounded look at the future of meat. You can even join the waitlist to receive updates and early access when these products become available in the UK.

Whether you're a flexitarian, a tech-savvy foodie, or just curious about what’s next in the food world, Cultivated Meat Shop delivers the resources and previews you need to stay ahead of the curve.

Conclusion

Scaffolding technology has made it possible to produce whole cuts like steaks and chicken breasts in a controlled and consistent way [4]. By replicating the natural extracellular matrix, scaffolds guide muscle cells into fibrous structures that mirror the texture of traditional meat. The seven products highlighted here showcase how companies are leveraging plant-based materials, 3D bioprinting, and precision techniques to create cultivated meat that looks, cooks, and tastes just like its conventional counterpart.

These advancements go beyond just replicating texture - they tackle some of the biggest challenges in our food system. Traditional livestock farming is responsible for around 14.5% of global greenhouse gas emissions [3], while cultivated meat has the potential to significantly reduce this impact, cutting land use by as much as 63–95% [21]. It also eliminates the need for animal slaughter and lowers public health risks associated with intensive farming methods [3]. This combination of technological progress and environmental responsibility represents the transformative potential discussed throughout this article.

The work of companies like Good Meat, Believer Meats, Meatable, Aleph Farms, Mosa Meat, Wildtype, and Upside Foods exemplifies how cultivated meat can deliver on both quality and sustainability. As these innovators move from regulatory approval to commercial production, they’re setting the stage for enjoying perfectly textured steaks without harming the planet or animals. These breakthroughs align with Cultivated Meat Shop's vision of a future where ethics, sustainability, and exceptional quality come together seamlessly.

FAQs

What is scaffolding in cultivated meat?

Scaffolding in cultivated meat serves as a three-dimensional framework that allows animal cells to grow and organise into tissue-like structures. It imitates the extracellular matrix (ECM) found in natural tissues, providing a surface for cells to attach and develop. Typically made from edible, food-safe materials, scaffolds are crucial for achieving realistic textures in products like steaks or fillets, ensuring cultivated meat looks and feels similar to traditional cuts.

Why are whole cuts harder than burgers to make?

Creating whole cuts is much trickier than making burgers because it means mimicking the intricate structure of real meat. This includes replicating the complex tissue layers and the way cells are organised. To pull this off, you need to tackle challenges like designing effective scaffolds, ensuring nutrients flow properly, and guiding cells to develop in the right way. All of this is essential to achieve a texture and look that closely matches traditional meat cuts.

When will these products be sold in the UK?

Cultivated meat products are expected to hit the UK market by around 2027. The Food Standards Agency is collaborating with companies to ensure these products comply with safety regulations, aiming for approval within that timeframe.